Skip to the content

Our Shop is equipped with only Modern Multi-axis CNC equipment

- All machines are outfitted with Intuitive probing systems to ensure part accuracy,

quality, and greatly improve setup times. - All of our CNC machines are equipped with automatic tool setters and high speed

machining functionality.

Modern Mitutoyo full Scanning CNC Coordinate Measuring Machine

- Capable Machining Starts with Capable Inspection

Simultaneous 5 Axis Machining Capabilities

- Components up to 1000lbs and 30” diameter.

- High speed 12,000 Rpm Spindle for better finishing and shorter cycle times.

Large Capacity CNC Milling in both Horizontal and Vertical Configurations.

- Horizontal milling up 64” x 120”

- 4 Axis Capability up to 10,000 pounds

- 4 Axis Machining of round components up to 36” Diameter.

Modern CNC Lathe

- 3000 rpms to support turning / threading operations with high finish requirements

- Gear box driven spindle to reduce cycle time and add efficiency to metal removal.

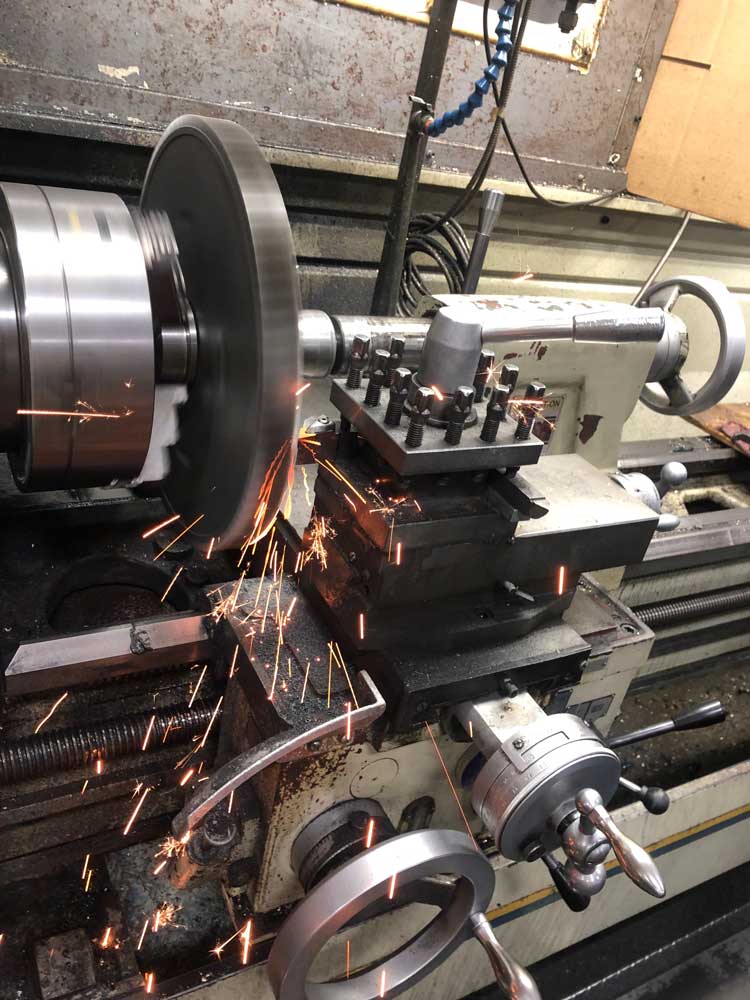

Manual turning and Milling Capability

- We are proud of our team at BMT, no one is more a part of that team than our manual

machinist with over 50 years of manual lathe experience alone.

LARGE CAPACITY OVERHEAD CRANE

- 5 Ton overhead Crane spanning our entire shop benefits Machining, inspection, and all support equipment.

TYKMA LASER ETCHING

- Provides our customers with 100% Traceability and part identification, also used for branding with logos and markings of any kind.

Fully Automatic Bandsaw with 12” Round or Square Capacity

- Fast, Accurate, Unattended sawing results in Less material waste, more spindle uptime, and more capacity to help our customers compete.